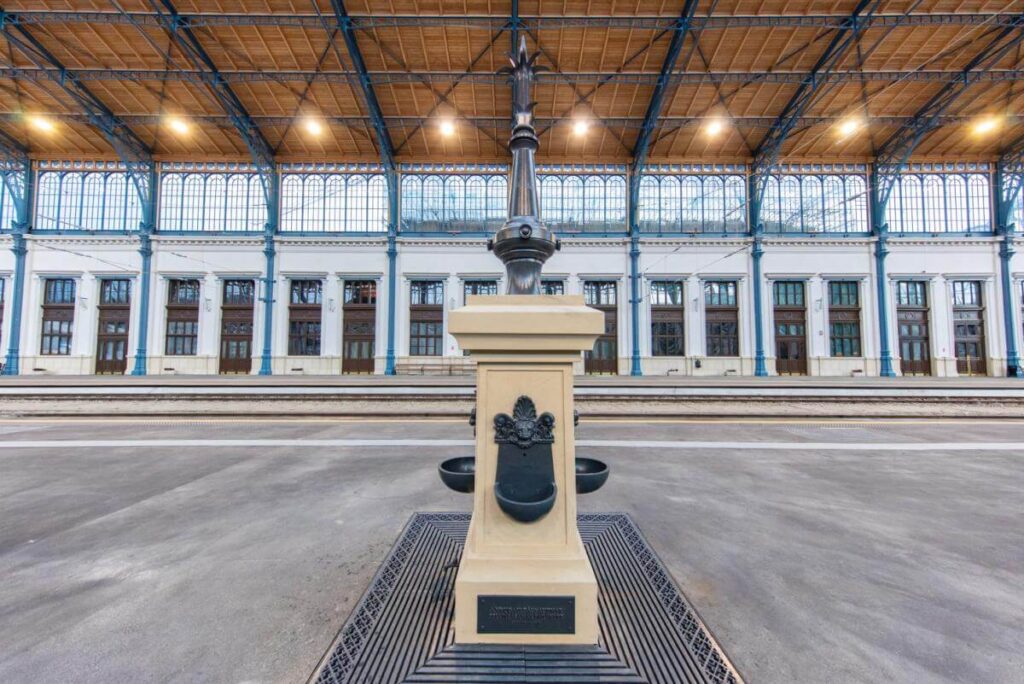

Track hall glazing | West Railway Station

In October 1877, one of Budapest's oldest railway main stations, Nyugati pályaudvar, opened its doors. The condition of the imposing building under monument protection - which in previous years handled an annual passenger traffic of around 18 million people by handling around 480 trains per day - was constantly deteriorating, so its renovation became timely.

The replacement of more than 1,700 m² of glass on the roof structure of the track hall was performed by Rákosy-Glass Kft. After removing the old wire-mesh cathedral glasses, 5.4.2 ESG VSG (hardened, laminated) layered cathedral glasses were manufactured and then installed in the new reception structure. The glass thickness and layer order were determined by the designer based on the technical and monument protection regulations. In order to avoid excessive heating of the hall, the use of sun protection glass would have been justified, but this is not permitted due to its highly reflective surface. So that the hall does not get too hot, but retains its light, the designer decided to install cathedral glass with a cloud pattern. This special type of glass diffuses the light excellently in the hall, and also matches the beautiful age of the building.

The so-called basilica lighting surface on the sides of the building is about 1,600 m². Many of the original metal mounting tabs were missing from these glasses, we produced them individually. The side glasses, shaped in several places, are made of clear glass with 4.4.2 VSG (glued safety) layering. Shaped glasses containing semicircular arcs were assessed by hand, using template technology, because size differences occurred in several places. This involved surveying approximately 3,300 windows.

The facade glazing on the main and end facades of the building, with a total size of approximately 1100 m², was completed with the same technical content.

During the renovation, we faced many challenges. Among the specifications was that during the work, as a supplement to the original mechanical fastening, the glasses must also be glued into the frame. In order to achieve a uniform façade appearance, our company custom-made a blue silicone sealant that matches the original image of the railway company, of which approximately 11 kilometers were used during the installation.

The highest point of the 146-meter-long and 42-meter-wide main hall is 25 meters high, so the glazing of the roof structure was partly carried out using scaffolding and partly using alpine technology. For the craneing of the glasses, we designed individual frames, which were lifted into the building using a tower crane, and then transported by hand to their place of installation. The technical acceptance took place after flooding the roof with water.

We are proud that we were able to take part in the renovation works of the Nyugati railway station, and that with our expertise and high-quality work we were able to contribute to the worthy renewal of this historically important building and to its continued brilliance for many decades.

General contractor: Magyar Építő Zrt.

Photos: Magyar Építő Zrt.