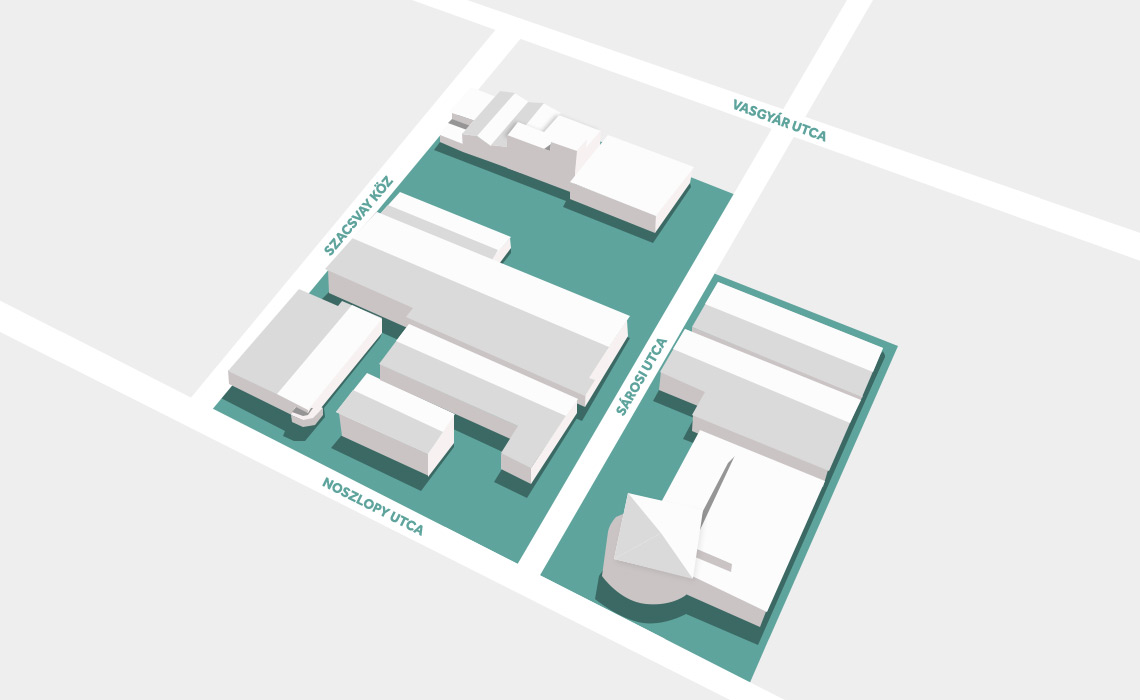

Our factory

PLEASE CLICK ON THE ICONS FOR MORE INFORMATION

Thermo plant and machine shop

The main building – purchased in 2009 – underwent comprehensive renovations. In 2010 a new section has been added, thus developing a 1670 m2 area large building, 4 stories tall in certain sections. Freight elevators and a 3.2 ton capacity bridge crane assist our colleagues in performing their work. The assembly of multilayered heat insulation glass and cabinets takes place in the building. This is where one of our bending furnaces is located as well, with the capability of taking in even a jumbo sized glass panel (6000 x 3210 mm). The increased demand for machining work demanded that we develop another new machine shop facility, which was also placed in this building. From 2013 onward, this building has been hosting a wood shop and associated retail store, so that our customers could one-stop shop – in addition to the glass and mirrors – for the necessary, custom-cut furniture boards with the right edging, along with all associated fittings. Our central water softening equipment was also placed in this building.

Machine shop facility

In 2006 we purchased the industrial lot adjoining the tailoring plant, with a 473 m2 hall. Once the hall was renovated, the third bending furnace of the firm was placed here, as well as the metalworking machines required for the manufacture of bending forms and to enable maintenance. This is where our experts manufacture custom fittings as well.

Tailoring plant, engineering office

Unveiled in 2008, the 2170 m2 hall hosts 2 Lisec cutting tables, and the glass warehouse with its automated glass warehouse of 49 racks (jumbo sized: 6000 x 3210 mm), with its dedicated gantry-crane, as well as a manual mounted rack warehouse for the storage of special glass products. 2 bridge cranes, each with a loadbearing capacity of 5 tons, assist smooth operations in the hall. This is also where the cutting table required for work processes that demand special, manual cutting is located. Colleagues engaged in the management of the company and in design are working in the engineering office that is located in the hall.

Glass grinder and surface treatment plant

We moved to the 10th District site in 1998. We perform the chamfering of residential orders in this 775 m2 building. This building hosts two industrial glass grinder machines, two armed industrial glass grinder machines, a faceting machine, a glass sawing mill and an industrial drill. The workshop includes equipment for surface treatment based on sand blowing and chemical processes. Alongside the colleagues who are working in the customer service room for retail sales, the associates of the sales group and the cash register have also been situated here.

Decorating workshop, materials warehouse

Decorating workshop, materials warehouse

At the time of the move from the 14th District site, the 312 m2 building with the small glass grinder plant was already a given. The decorating workshop is located inside the building; this is where our associates prepare the glass for painting and surface treatment. This building also hosts the materials warehouse.

Laminating workshop

After the 1998 purchase of the facility, this was the first hall that was built in 2000. It has an area of 880 m2, which has initially hosted a custom cutting table and a glass warehouse. The custom cutting operation has since moved on; since then, we have been using the entire building exclusively for work processes that are required for lamination operations. In the hall, 2 Tornati Forni EVA technology furnaces are operating, with a maximum intake capacity of 5000 x 2700 mm. The effective performance of the work is assisted by a 5 ton load bearing capacity bridge crane and 2 revolving cranes, each with a 200 kg load bearing capacity.

Office building

In the interest of serviving our customers in a more comfortable and nicer environment, the development is a multi-storey, 302 m2 in area office building is taking place at our site. We would like to receive our purchasers here in the second half of 2024.

Hardening plant, fittings warehouse

This is the building where we placed our new NorthGlass model glass tempering furnace in 2020. Here, the heat treatment of glass panels with a maximum size of 2800 x 6000 mm is possible, and the bending of glass only takes a few minutes. A KeraGlass rolling coating machine is located in the hall as well. The painter colleagues who work in the hall do their jobs at the rolling coating machine, or in the case of individual projets, by utilizing screen tables and a coating booth. The cluster of buildings hosts a great deal of equipment and technology, including CNC work stations, chamfering machines, and specialized industrial drills. The performance of the work is assisted by two bridge cranes with load bearing capacities of 3.2 and 2 tons, respectively. Located in the hall, our glass fitting warehouse awaits customers with a wide selection of products and colleagues prepared to answer their questions.

Thermo plant and machine shop

The main building – purchased in 2009 – underwent comprehensive renovations. In 2010 a new section has been added, thus developing a 1670 m2 area large building, 4 stories tall in certain sections. Freight elevators and a 3.2 ton capacity bridge crane assist our colleagues in performing their work. The assembly of multilayered heat insulation glass and cabinets takes place in the building. This is where one of our bending furnaces is located as well, with the capability of taking in even a jumbo sized glass panel (6000 x 3210 mm). The increased demand for machining work demanded that we develop another new machine shop facility, which was also placed in this building. From 2013 onward, this building has been hosting a wood shop and associated retail store, so that our customers could one-stop shop – in addition to the glass and mirrors – for the necessary, custom-cut furniture boards with the right edging, along with all associated fittings. Our central water softening equipment was also placed in this building.

Machine shop facility

In 2006 we purchased the industrial lot adjoining the tailoring plant, with a 473 m2 hall. Once the hall was renovated, the third bending furnace of the firm was placed here, as well as the metalworking machines required for the manufacture of bending forms and to enable maintenance. This is where our experts manufacture custom fittings as well.

Tailoring plant, engineering office

Unveiled in 2008, the 2170 m2 hall hosts 2 Lisec cutting tables, and the glass warehouse with its automated glass warehouse of 49 racks (jumbo sized: 6000 x 3210 mm), with its dedicated gantry-crane, as well as a manual mounted rack warehouse for the storage of special glass products. 2 bridge cranes, each with a loadbearing capacity of 5 tons, assist smooth operations in the hall. This is also where the cutting table required for work processes that demand special, manual cutting is located. Colleagues engaged in the management of the company and in design are working in the engineering office that is located in the hall.

Glass grinder and surface treatment plant

We moved to the 10th District site in 1998. We perform the chamfering of residential orders in this 775 m2 building. This building hosts two industrial glass grinder machines, two armed industrial glass grinder machines, a faceting machine, a glass sawing mill and an industrial drill. The workshop includes equipment for surface treatment based on sand blowing and chemical processes. Alongside the colleagues who are working in the customer service room for retail sales, the associates of the sales group and the cash register have also been situated here.

Decorating workshop, materials warehouse

Decorating workshop, materials warehouse

At the time of the move from the 14th District site, the 312 m2 building with the small glass grinder plant was already a given. The decorating workshop is located inside the building; this is where our associates prepare the glass for painting and surface treatment. This building also hosts the materials warehouse.

Laminating workshop

After the 1998 purchase of the facility, this was the first hall that was built in 2000. It has an area of 880 m2, which has initially hosted a custom cutting table and a glass warehouse. The custom cutting operation has since moved on; since then, we have been using the entire building exclusively for work processes that are required for lamination operations. In the hall, 2 Tornati Forni EVA technology furnaces are operating, with a maximum intake capacity of 5000 x 2700 mm. The effective performance of the work is assisted by a 5 ton load bearing capacity bridge crane and 2 revolving cranes, each with a 200 kg load bearing capacity.

Office building

In the interest of serviving our customers in a more comfortable and nicer environment, the development is a multi-storey, 302 m2 in area office building is taking place at our site. We would like to receive our purchasers here in the second half of 2024.

Hardening plant, fittings warehouse

This is the building where we placed our new NorthGlass model glass tempering furnace in 2020. Here, the heat treatment of glass panels with a maximum size of 2800 x 6000 mm is possible, and the bending of glass only takes a few minutes. A KeraGlass rolling coating machine is located in the hall as well. The painter colleagues who work in the hall do their jobs at the rolling coating machine, or in the case of individual projets, by utilizing screen tables and a coating booth. The cluster of buildings hosts a great deal of equipment and technology, including CNC work stations, chamfering machines, and specialized industrial drills. The performance of the work is assisted by two bridge cranes with load bearing capacities of 3.2 and 2 tons, respectively. Located in the hall, our glass fitting warehouse awaits customers with a wide selection of products and colleagues prepared to answer their questions.