Fused glass

The essence of fusion technology is to create forms with the aid of a template, using the appropriate temperature, by changing shape. Fusion occurs in a fusion furnace, at an approximate temperature of 800-1000 Degrees Celsius, with the aid of either a gypsum or metal template.

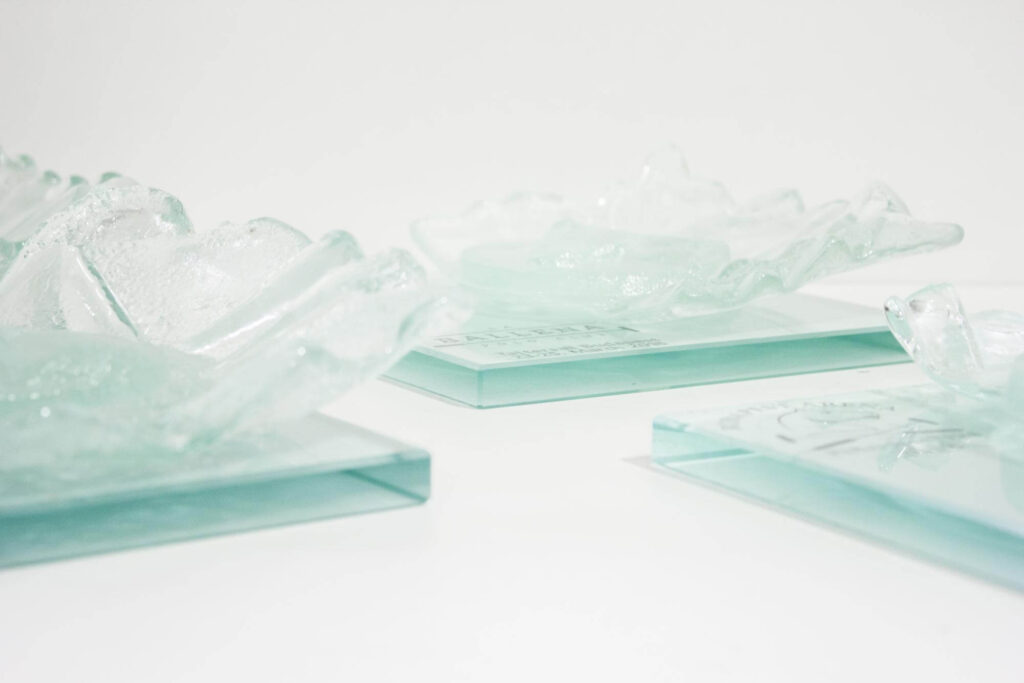

The degree to which the glass layers melt into one another can be influenced by changing the temperature and the duration of the heating period; this way, unique and special shapes can be created. It is most frequently used for bathroom sinks, but sculptures, lamps, trophies, and various decorative glass objets can also be manufactured with this technology. Fusion translates into one of the most unrestrained glass processing technologies, allowing for an infinite variety of colors, patterns and shapes. Fused glass cannot be tempered, it mostly serves a decorative function.

SIZE LIMITATIONS

- Minimal size: 200 x 300 mm

- Maximum size: 2400 x 4500 mm

Top technologies in Glass Processing

Precision and quality in every single product

Why

choose us?

Rákosy Glass only makes unique glass products tailored to your needs.

We boast decades of experience and numerous industry awards as a guarantee of quality.

We deliver your projects on time and to the highest standards, thanks to our on-site manufacturing.

With the help of our modern machines and advanced techniques, we undertake even the most complex and creative glass processing tasks.

With our environmentally conscious production processes, we contribute to the sustainability of architectural projects.