made from 88 custom glass panels

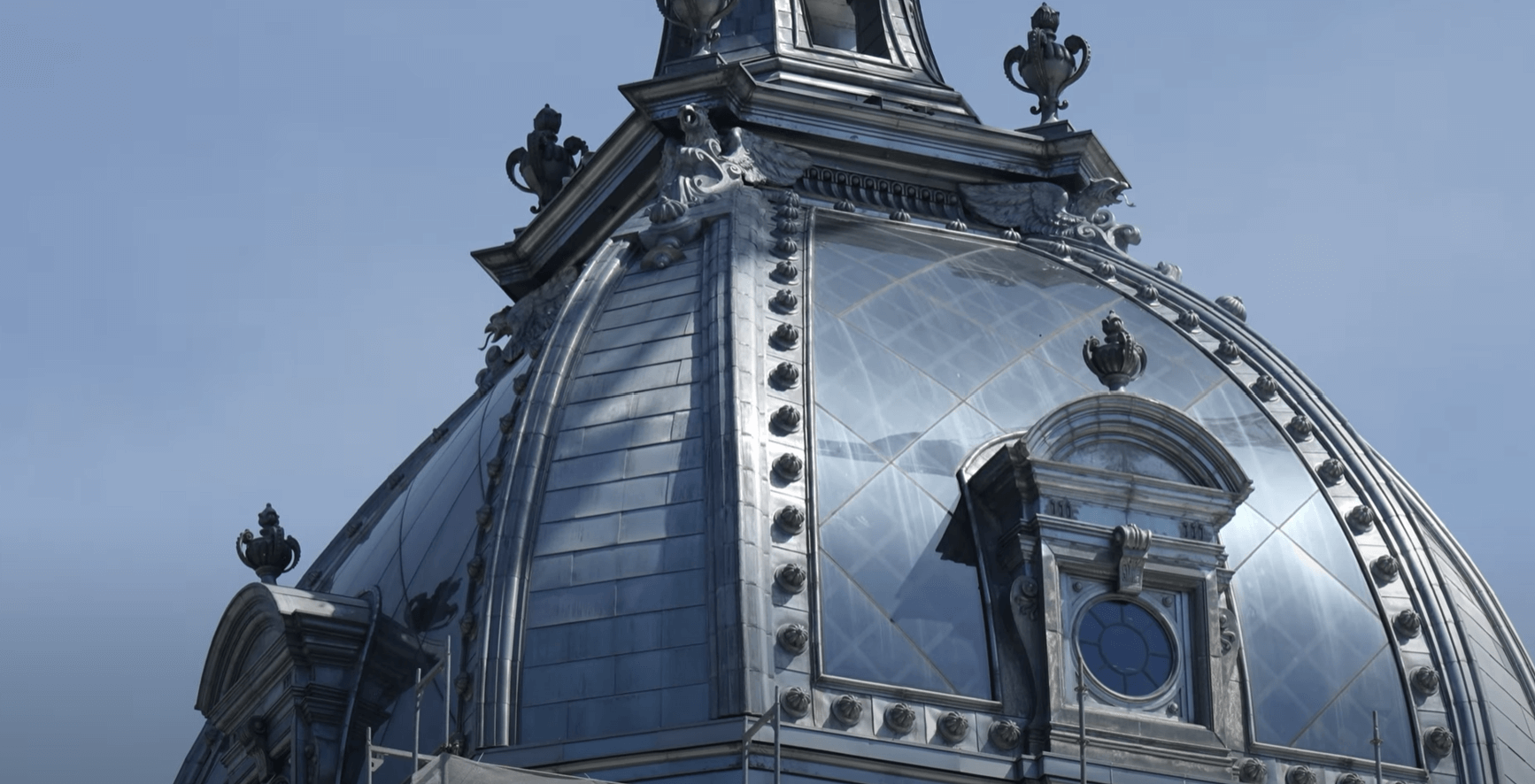

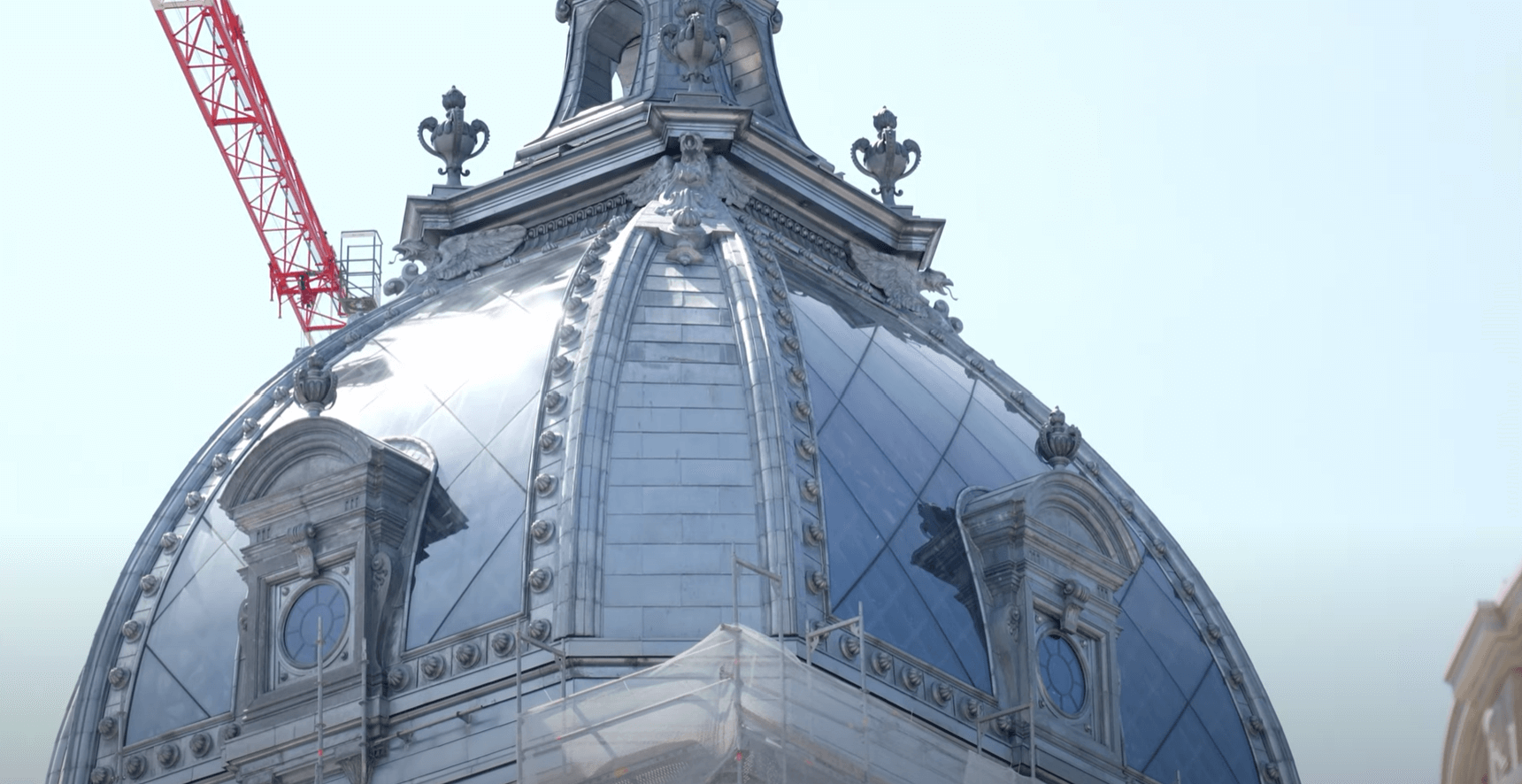

the renewed dome of the Hungarian Defence Forces Headquarters

Heritage and innovation are not mutually exclusive

The second-largest and most ornate dome of Buda Castle — the reconstructed rooftop crown of the Hungarian Defence Forces Headquarters — stands out as an exceptional architectural and engineering achievement. During the construction of the 15-meter-high and 9-meter-wide dome, composed of curved glass surfaces, Rákosy Glass played a key role in the complete design and production of the glass structures.

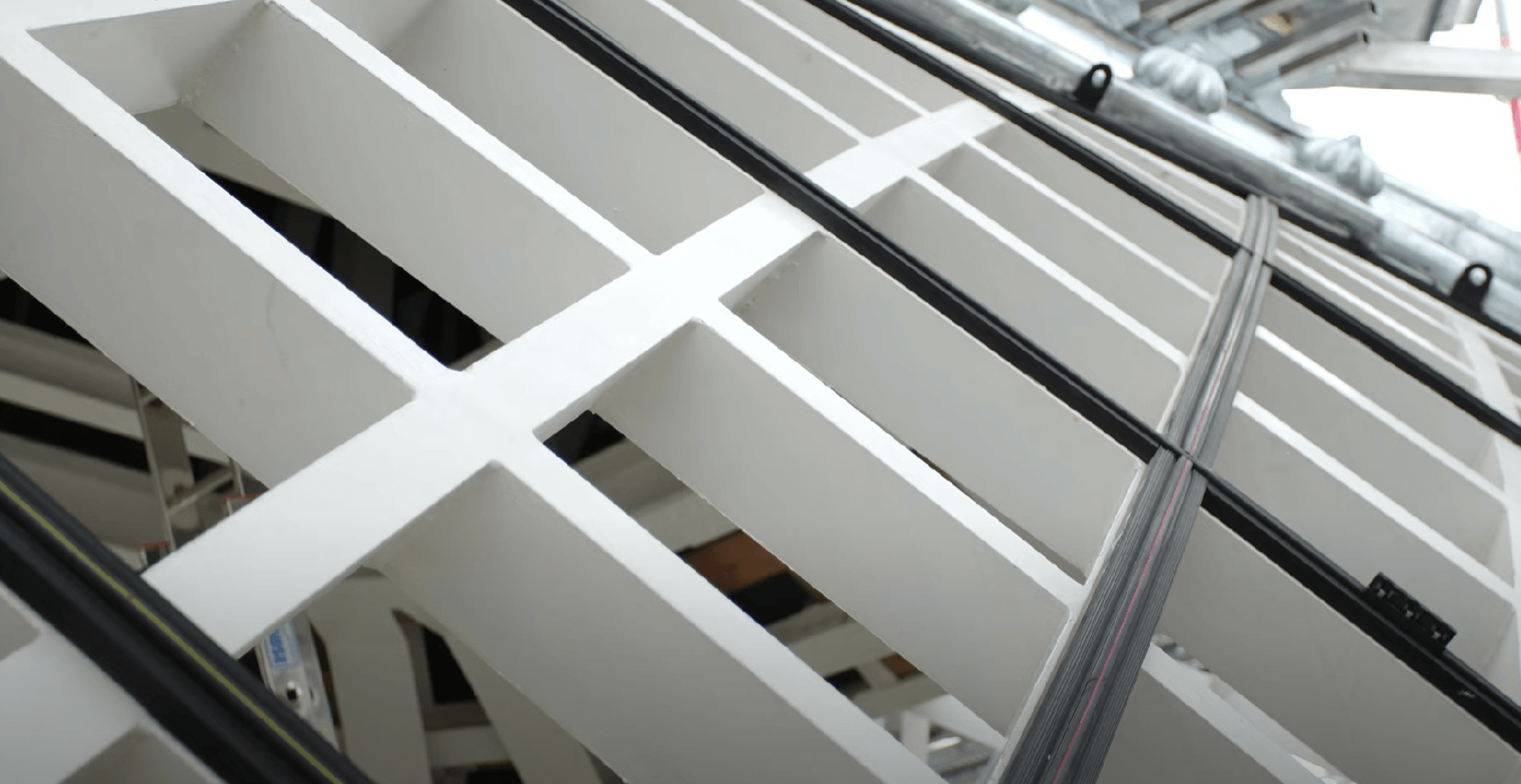

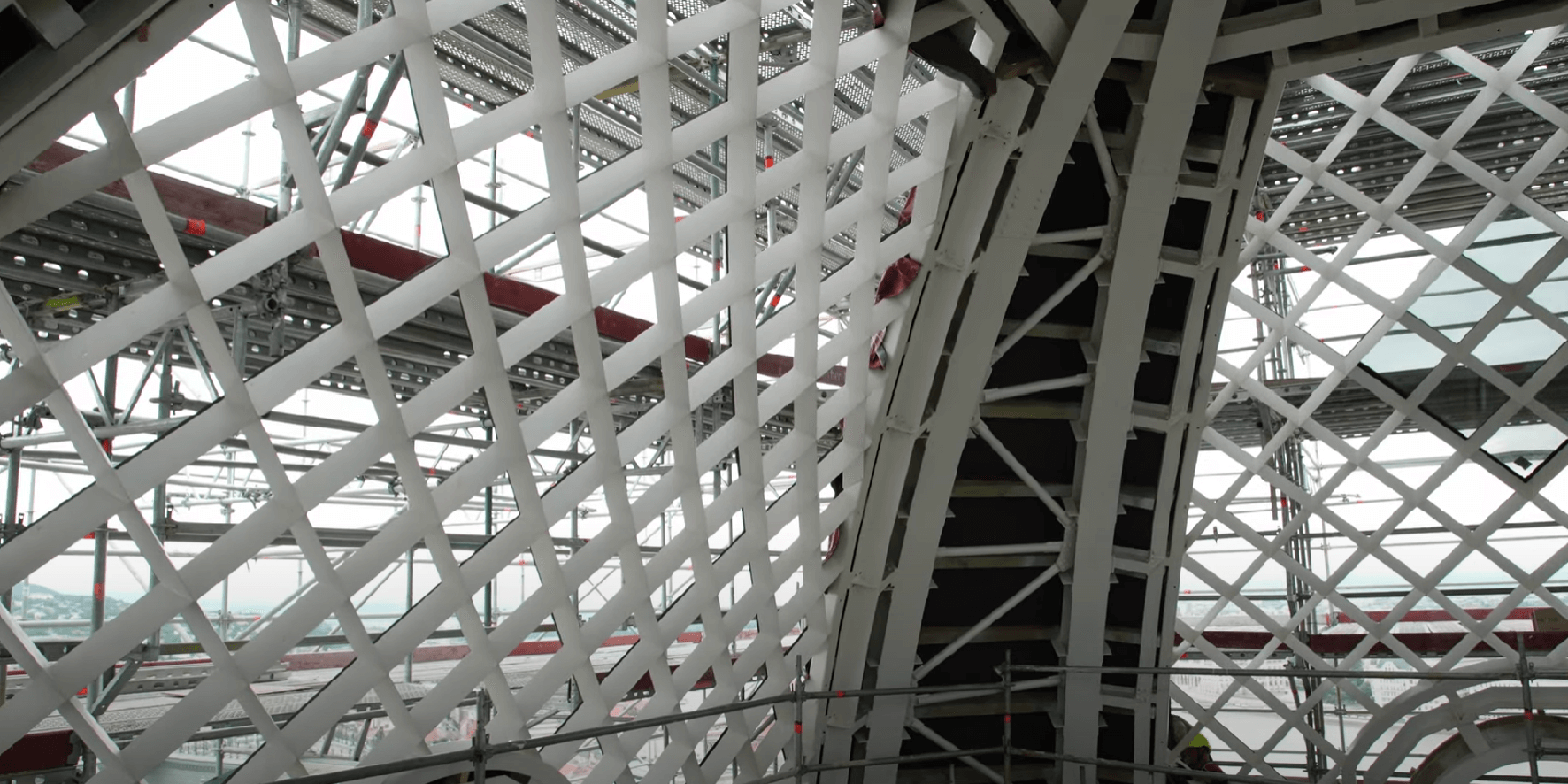

The margin for construction inaccuracies had to be virtually reduced to zero – especially critical in the case of the curved steel segments and the curved glass panels attached to them.

Material Use and Technological Solutions

The profile system was originally planned in steel, but due to the need for precise bending of the curves, they switched to aluminum. This made it possible to achieve arches that are both technically and aesthetically perfect. The fastening solution is hidden, and the sealant between the glass panels is UV-resistant silicone. Every detail of the execution was characterized by the highest standards of quality and precision.

Reconstruction with a completely new function

Anyone who loves admiring urban landscapes knows the feeling that fills the soul when climbing a church tower or reaching the top of a tall building and taking in the panoramic view. The new dome rises more than 50 meters above the level of Dísz Square. Thanks to its glass cladding, it is now possible to enjoy the unique panorama of Buda Castle from within the dome itself. We are delighted to have contributed to the creation of this new tourist attraction.

Top technologies in Glass Processing

Precision and quality in every single product

No terms found for this post.

Glass structures

custom shapes, precise fittings

The glass elements of the dome were typically rhombus-shaped or had complex, irregular geometries. The finished curved glass components are triple-layer insulated glass units, which required the following technological steps:

Cutting to size, edge grinding

Custom-radius bending in a tempering furnace

Lamination with safety film

Integration of a special aluminum profile into the glass edge (for mechanical fastening)

Structural mounting onto an aluminum laying profile

Insulating glazing filled with krypton gas (not argon)